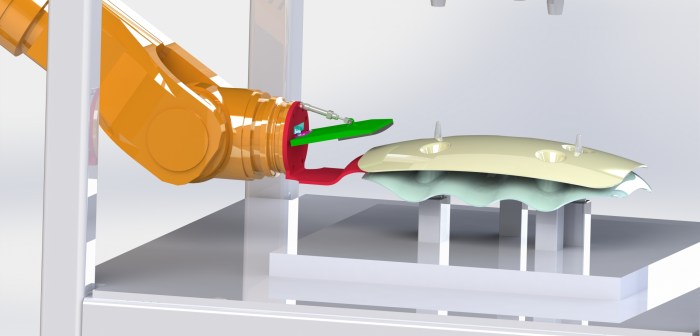

This project required us to design an end effector for the Kuka KR 30 Robotic arm to be able to place and move two heat shield parts into a welding station. After the parts have been welded the end effector had to be able to pick up the new weld part and place it on an adjacent rack. This required me to convert a surface model of a Kuka KR 30 into a solid pieces to later assembly into a flexible arm. Once the arm was made, I had to design the end effector, mount it to the arm, and then configure the arm for its routine. I have attached some pictures of the arm at work as well as the end effector design.

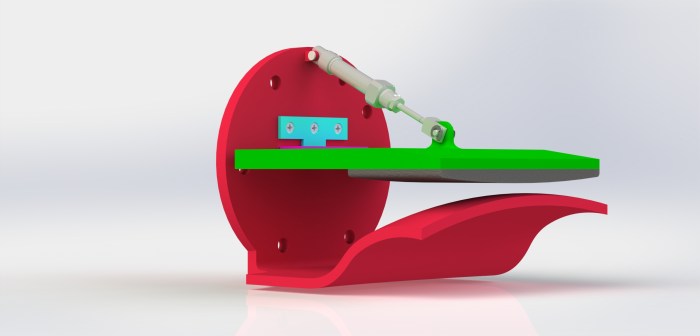

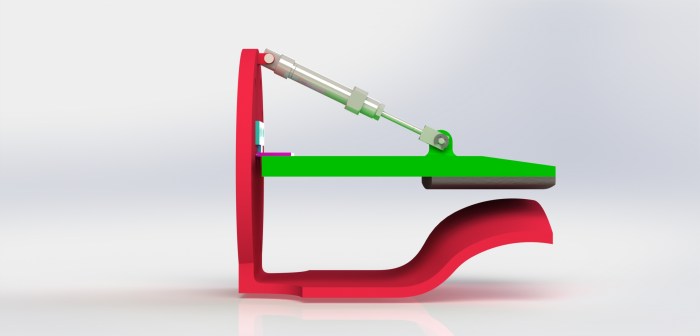

Claw assembly:

Assembly: